Decompression gets a new trailer

Printed From: Laser 28 International Class Association

Category: Laser 28 General

Forum Name: General Forum

Forum Description: All the topics that don't fit elsewhere

URL: http://www.laser28.org/forum/forum_posts.asp?TID=859

Printed Date: 10 April 2025 at 9:01pm

Software Version: Web Wiz Forums 11.03 - http://www.webwizforums.com

Topic: Decompression gets a new trailer

Posted By: Foghorn

Subject: Decompression gets a new trailer

Date Posted: 10 December 2020 at 1:10pm

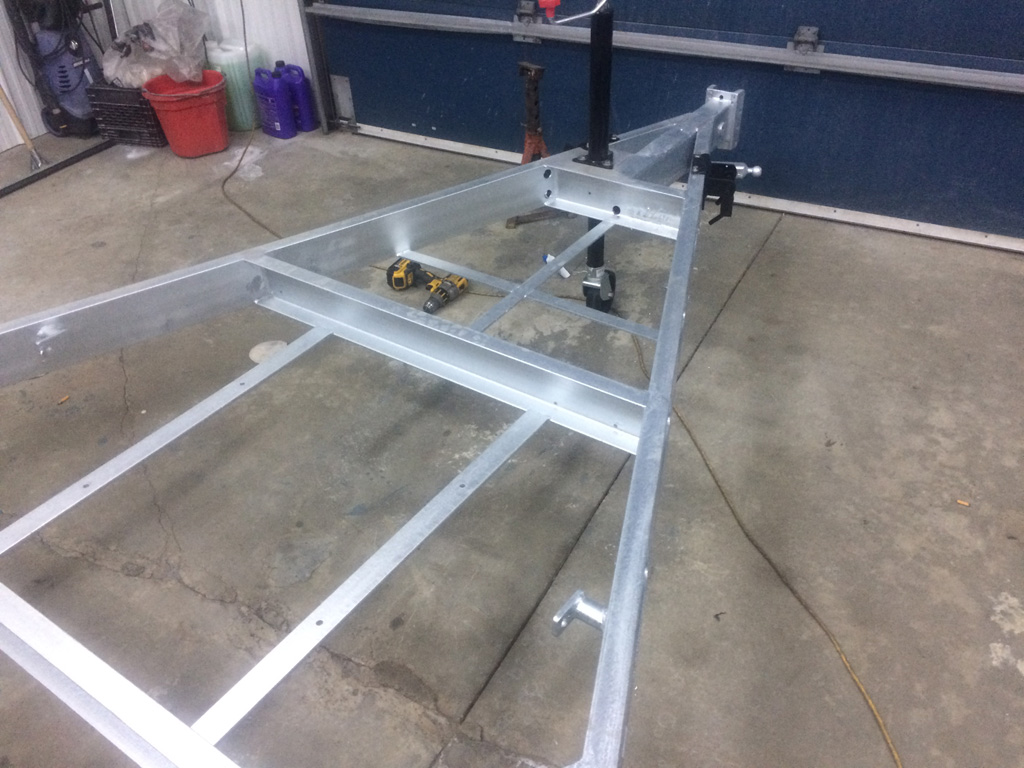

|

I had been thinking of building a trailer for a while now and finally the opportunity came up this year. With lots of time on hand early this year, my friend Simon T and I conceived the idea of a trailer in AutoCAD over a remote connection incorporating ideas I had accumulated and being suitable for Decompression to relax on.    One of the main features is that the supports are removable in order to reconfigure the trailer with a wood deck and/or sides if desired. Another feature is the addition of a 7th support pad along the centerline at the rear. The boat is solid glass along the centerline and the pad sits just behind the engine bed and in between the two longitudinal ribs. This is a very strong area that takes some weight off the two conventional rear pads which sit against the cored hull, some boats show flat spots here from the weight compressing the laminate. The pads are 3/4 inch rubber tread on top of 1 inch RV stable plastic with stainless fasteners.     Axles are tandem 3,500 pound prestressed drop axles utilising 3 inch tubing. 2 1/4 x 10 inch electric brakes at each wheel with a battery backup break away system (mounted near the spare tire) to apply the brakes if the switch triggers during uncoupling. The spring and balancer mounts were strengthened and bolts with grease nipples are used at all spring and balancer points. Wheels are zero offset galvanised trailer rims rated at 2,250 pounds, tires are Goodyear Endurance 205/75/15 rated for 2,500 pounds at 65 psi. These tires are for trailer use only and feature very stiff sidewalls.   Up front is a slide lock 2 5/16 inch coupler mounted with grade 8 bolts to an adjustable channel for optimal trailer leveling and potentially other coupler types. Safety chains are 6,000 pound 5/16 inch galvanised chain. Where the safety chains mount to the tongue there is sleave welded inside the tubing for stiffness and custom spacers on the outside to attach the chains tight and flat with the through bolt.    The small ball welded to the square tubing is for the anti-sway bar. The torsion bar brackets are bolted to the trailer using two tapped bolts and 2 through bolts. The ball is mounted this way for clearance when turning left. The fenders have 14 gauge sides and are removable with reinforcing plates front and back, all the components are powder coated. LED lighting is used throughout the trailer. There are 5 junction boxes for the wiring, one at the front, two on each side for the brakes and lighting and two more at the rear. There are no splices anywhere, all connections are inside the boxes using soldered ring terminals and heat shrink. There is a 7 wire ran all the way to the back and auxiliary 12 volt power at each box, water proof connectors are used throughout. Reverse lights are also used. The license plate bracket is custom made with a full-length hinge and powder coated.  The trailer weighs 1,565 pounds empty, less than 50 pounds over the calculated design weight. I consider the trailer to have a 7,000 pound Gross Vehicle Weight Rating (GVWR) though the tires and wheels can support more weight but the idea is not to run the tires at their maximum weight rating for longevity and safety. I've had the truck and trailer on a truck scale while empty and loaded.  Pulling the trailer empty with the torsion bars lightly loaded is almost imperceptible behind the truck, the Silverado has a 153 inch wheelbase so it's very stable. Pulling with boat loaded is certainly noticeable but the trailer tracks like a dream. 12 feet 9 inches clearance is required for the boat and trailer as configured in the photos.     ------------- Paul White Decompression CAN 214 |

Replies:

Posted By: Ron Waterson

Date Posted: 10 December 2020 at 4:54pm

|

That looks awesome Paul! Nice work. ------------- Hull 147 - Angel's Share |

Posted By: John Mills

Date Posted: 10 December 2020 at 5:34pm

|

Are you planning some road travel to regatta's ? ------------- Unplugged # 164 NOTL |

Posted By: Foghorn

Date Posted: 11 December 2020 at 5:55pm

That may be a possibility, though I would imagine more so for 2022 than 2021 given the current situation. ------------- Paul White Decompression CAN 214 |

Posted By: Ron Waterson

Date Posted: 11 December 2020 at 7:17pm

|

Just throwing this out there, but there are at least two of us here in Louisville that would travel to crew at Laser 28 OD regatta. Can work any position on the boat. Agree with the 2022 sentiment. Or at least after vaccinations are common. Have bourbon will travel! Ron ------------- Hull 147 - Angel's Share |

Posted By: Geoff Coke

Date Posted: 14 January 2021 at 11:37pm

|

I have been dreaming of a trailer. Looks great. Now to convince the finance committee!

|

John Mills wrote:

John Mills wrote: