|

Useful life of spars |

Post Reply

|

| Author | |

charlesadan

Rookie

Joined: 10 September 2012 Location: Camden, ME Status: Offline Points: 5 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Useful life of spars Topic: Useful life of sparsPosted: 18 August 2016 at 12:51pm |

|

I'm making some decisions about maintenance/upgrades that require me to think longer term about my Laser 28.

One concern I have is that the aluminum mast (especially the tapered masthead) may require replacement at some point. I'm not sure how much that might cost or whether it's even possible. Is this something that should be done proactively? I don't really want to wait until it fails. My boat is 31 years old, and as far as I can tell nothing is wrong with the spars, but I've been wondering if others here have thoughts about how long the "useful life" should be? Has anyone out there had to replace/repair their mast or boom?

|

|

|

|

John Mills

Commodore

Joined: 01 February 2016 Status: Offline Points: 122 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 August 2016 at 6:14pm Posted: 21 August 2016 at 6:14pm |

|

Be more concerned about the chain plates . Glass them in .

|

|

|

Unplugged

# 164 NOTL |

|

|

|

charlesadan

Rookie

Joined: 10 September 2012 Location: Camden, ME Status: Offline Points: 5 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 August 2016 at 6:25pm Posted: 21 August 2016 at 6:25pm |

|

Funny, the chainplates on my boat (#138) appear to be in such pristine condition that it's far down on my list of concerns (now I supposed they are guaranteed to fail on my next outing).

|

|

|

|

bal149

Skipper

Joined: 14 August 2010 Location: canada Status: Offline Points: 67 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 August 2016 at 6:33pm Posted: 23 August 2016 at 6:33pm |

|

If I sight up the mast on Balaou, with wind 10 knots or more one sees the unsupported top part of the mast leaning to leeward. Looking at the unstepped mast there is a bit of rippling just above where the shrouds attach so definitely the mast works hard. What this means in terms of longevity , I cannot begin to guess. Perhaps someone more knowledgeable can answer this question.

Edited by bal149 - 23 August 2016 at 8:02pm |

|

|

|

John Mills

Commodore

Joined: 01 February 2016 Status: Offline Points: 122 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 August 2016 at 10:17pm Posted: 25 August 2016 at 10:17pm |

|

The chain plates are held in by the glued in shelf down below (part of the grid) . They are not glassed into the hull . This glue eventually fails and they pull away . All that is then holding the mast up is your through deck fitting . Mine are fine , but on the Laser beside me, # 133 they failed on and we caught it and he fixed it . You don't really know how well they are still holding on until you are out in a blow . I will proactively glass mine in this fall, there are posts on doing it in this forum .

|

|

|

Unplugged

# 164 NOTL |

|

|

|

frfletch

Commodore

Joined: 13 May 2008 Location: Canada Status: Offline Points: 365 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 August 2016 at 1:27pm Posted: 26 August 2016 at 1:27pm |

|

Hold the phone on glassing in chainp lates. That is ridiculous. Per se, there are no chain plates on the laser. What you are calling a chain plate is only a transfer plate as all the tension goes down to a nav-tec rigging rod that in-turn screws into a solid block of stainless steel that is glassed to the inside of the structural grid system of the boat. The chain-plate as you see at the deck only locates the shroud where it connects to that rod. It is not an anchor point for the shroud in the typical sense, and is a place to seal the entrance to the hull to prevent leakage. When setting up the rigging, one should tighten the rod so that there is some downward pressure at the deck to allow for the uplift when the rigging is tightened. The objective is to have the pressure on the deck as neutral as possible. Don't glass it in.

|

|

|

|

Bill Layton

Commodore

Joined: 15 September 2002 Location: Canada Status: Offline Points: 551 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 August 2016 at 1:52pm Posted: 26 August 2016 at 1:52pm |

|

It's not the chainplate that needs to be glassed in but the gluing flange of the liner that holds the tie-rod barrel. It's very common for this glued flange to pop out and the solution is to glass that flange back in place. I've recommended this update on all L28's for 25 years... early boats are more likely to fail in this area. I also extend the glass tape up the gluing flange of the vertical ring beam to tie it in well.

|

|

|

|

WJRyan

Commodore

Joined: 12 February 2008 Location: Louisville, KY Status: Offline Points: 230 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 August 2016 at 2:29pm Posted: 26 August 2016 at 2:29pm |

|

A picture could help tell a 1000 words -well, for me anyway. Not sure what to look for/at.

|

|

|

Bill Ryan,

Room4Crew, #155 |

|

|

|

John Mills

Commodore

Joined: 01 February 2016 Status: Offline Points: 122 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 August 2016 at 3:38pm Posted: 26 August 2016 at 3:38pm |

|

Seems the pictures on the Forum have expired . I will snap a pick of Greg's repair this week end - assuming he lets me , we are at a one design L28 race this weekend . Anyway I will post . It is obvious once you see it . The shelf above your galley table has a ss bar going into it and this shelf carries the rig through the SS bar not the deck . Sometimes this shelf pulls away from the hull, so you glass in the flange behind the soft locker and its all good - do both sides.

It is my guess that this is the most likely cause of lost rigs on this boat .

|

|

|

Unplugged

# 164 NOTL |

|

|

|

Mad Max

Skipper

Joined: 18 June 2010 Location: Buffalo NY Status: Offline Points: 55 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 August 2016 at 6:15pm Posted: 28 August 2016 at 6:15pm |

|

Gentlemen

A look behind the curtain. https://flic.kr/s/aHskHrhUxV Dick

|

|

|

Dick #122

|

|

|

|

Ron Waterson

Commodore

Joined: 21 October 2014 Location: Rivals, KY Status: Offline Points: 118 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 28 August 2016 at 7:34pm Posted: 28 August 2016 at 7:34pm |

|

Bill,

When you say "early boats", is there a specific hull number where construction of the flange changed/improved, or are you simply stating that the older the boat, the more likely the failure? Ron

|

|

|

Hull 147 - Angel's Share

|

|

|

|

John Mills

Commodore

Joined: 01 February 2016 Status: Offline Points: 122 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 August 2016 at 11:26am Posted: 29 August 2016 at 11:26am |

|

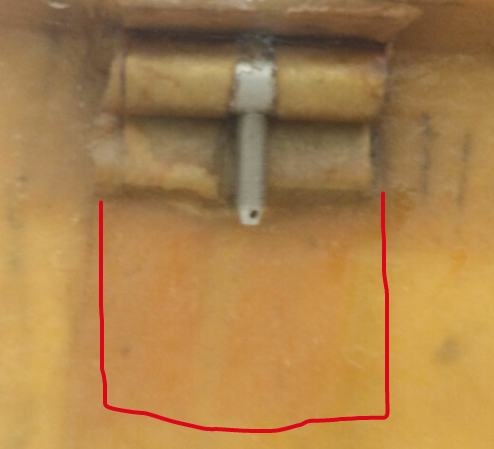

Great pictures , that is the inside . The chain plate is glassed into the shelf , nice and strong. Then the shelf is glued / attached to the hull (bill might know what they used ) and this glue joint is the one known to fail . So the shelf pulls free . Flip up the soft locker and glass in the flange you see and you should be good. A little preventive maintenance . The post "Rebirth of 214" has a picture of it glassed in , nice job . Just search for it and the pick is part way down , look for the one with the ss rod going in the shelf

|

|

|

Unplugged

# 164 NOTL |

|

|

|

Foghorn

Admin Group

Joined: 24 August 2002 Location: Montreal, QC Status: Offline Points: 120 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 August 2016 at 7:26pm Posted: 29 August 2016 at 7:26pm |

|

Here's a link to the Rebirth of 214 if that's of interest.

Here are pictures of where the tie rods attach to the rib structure and the glass work that was done;   Edited by Foghorn - 29 August 2016 at 7:27pm |

|

|

Paul White

Decompression CAN 214 |

|

|

|

Bill Layton

Commodore

Joined: 15 September 2002 Location: Canada Status: Offline Points: 551 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 August 2016 at 8:32pm Posted: 29 August 2016 at 8:32pm |

|

Ron, yes the more mileage a boat has the more likely this glued flange will unglue from the hull. It will happen to most of our boats so getting this job done before it fails just makes it easier to repair. Better sooner than later. When the flange pops the deck bows upwards at the chainplate. However I've never seen anyone damage their deck from it.

Dick, that pic you posted shows the gluing flange has been cut off so this is not what the standard boat looks like. It's a good pick though and does show the angle plate and tie rod barrel with glass tape holding it in place. A view you only see before the liner was glued in place... or in your case the whole area cut out?

|

|

|

|

John Mills

Commodore

Joined: 01 February 2016 Status: Offline Points: 122 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 August 2016 at 12:02pm Posted: 30 August 2016 at 12:02pm |

|

Flfletch - some confusion as to what we are referring to on chain plates . Normally the chain plate is considered the entire assembly that transfers the rig load to the hull , not just the little end of it that sticks through the deck . Many call the part that sticks through the deck the chain plate - it is just the tip of an assembly that transfers the rig load to the hull .

Anyway splitting hairs , you are correct do not glass the deck in it is not what is holding up the rig , it is the other end of the chain plate that is glassed into the shelf that carries the load transferring it to the shelf and through he shelf to the hull - it is the shelf assembly that pulls away . Thus the chain plate is no longer is attached to the hull. To be clear Glass the shelf in like the pictures show .

|

|

|

Unplugged

# 164 NOTL |

|

|

|

Virginia H.

Crew

Joined: 03 March 2012 Location: Hampton, Va Status: Offline Points: 46 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 September 2016 at 10:06pm Posted: 19 September 2016 at 10:06pm |

|

is reglassing the shelves and ring frame enough? Or Do you need to cut into or put an inspection plate in the area under the tie rod to make sure it is glassed in?

|

|

|

|

frfletch

Commodore

Joined: 13 May 2008 Location: Canada Status: Offline Points: 365 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 September 2016 at 11:06pm Posted: 19 September 2016 at 11:06pm |

|

Virginia,

Inside the longitudinal structural frame into which the Navtec rod goes, there is a hefty stainless steel block inside that frame and the rod screws into that block. The uplift on that block is resisted by the upper portion of the frame. The block is glassed in place just to hold it there. Glass and epoxy do not form a structural bond with stainless steel, so no need to see inside. |

|

|

|

Bill Layton

Commodore

Joined: 15 September 2002 Location: Canada Status: Offline Points: 551 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 September 2016 at 7:50am Posted: 20 September 2016 at 7:50am |

Some of the early boats have indeed failed in this area and we had to cut into the white glass liner where it bonds onto the hull underneath the tie-rod barrel. There is an angled edge approx, 18" lower than the tie-rod barrel, for example this is where the edge of the table sits when folded down against the side of the hull. It's the next loaded area after the flanges above. (the port side is similar) That edge is the bottom of the flat panel that extends downwards from the tie-rod barrel. I have seen this pull out on 2 early boats. One time the flange had popped and sailed popped for some time before being noticed which assumably led the lower part to let go and the other boat may have had an impact on the side of the hull. This last boat had it's flanges re-glassed some years earlier and then the lower part popped. It left that whole flat part of the white panel distorted and wrinkled. Once cut out and reglassed it was fine. To do any of these tie-rod repairs the boat has to be on the trailer or cradle with the mast down so those areas are not loaded. Furthermore, before I start the job I loosen the tie rods off and loosen the pads off on the trailer/cradle so that the boat is sitting nearly 100% on it's keel. After sitting like this for a day or two I always found the distorted glass fell back into place and I just had to cut into it and glass it into the hull (the bottom part), refair it and I usually coat it with white epoxy and leave it. As doing it in gelcoat would be very time consuming.

Edited by Bill Layton - 20 September 2016 at 7:51am |

|

|

|

Geoff Coke

Crew

Joined: 18 October 2018 Location: Rossland BC Status: Offline Points: 22 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 July 2022 at 12:06pm Posted: 02 July 2022 at 12:06pm |

Can I assume the shelf itself is providing the majority of the structural strength? Does anyone have any photos of how they glassed in the steel block holding the rod and the repair on how the glass shelf was cut out? Has anyone considered increasing the "height" of the steel block so it has additional bond to the vertical bulkhead? I would think that the structural strength would be stronger along the bulkhead length rather than relying on the "Z" of the shelf bend.  Edited by Geoff Coke - 02 July 2022 at 12:11pm |

|

|

|

Post Reply

|

|

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |